[info]Bored piles drilled using either permanent or temporary casing to prevent collapse.[/info]

Double Rotary Case Piles

[info]Micro piles also known as mini plies, pin piles, needle piles or root piles are small diameter drilled piles. They offer a viable alternative to conventional piling techniques particularly in the following conditions:[/info]

- Restricted access

- Low headroom

- Challenging subsurface conditions

- Environments sensitive to noise or vibrations

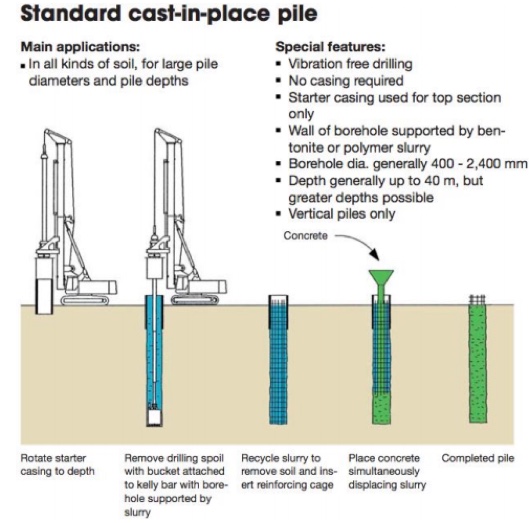

[info]Bored Piles are drilled under a head of slurry – either bentonite or polymer to mitigate collapse. Underslurry piles are ideal for deep foundations up to 68 meters deep using slurry to support the earth as the pile is being drilled.[/info]

The diagram below shows the standard procedure of casing installation, excavation, cleaning of the slurry; then installing the reinforcement cage, pouring the concrete and extracting the casing.

[info]FDP (full displacement piles) has many benefits of driven piles without the disadvantages of noise, vibration, joints and waste.[/info]

FDP are a type of reinforced concrete pile that are built in situ. This technology combines the advantages of driven (displacement piles) and bored piles (piles without displacement).

Despite being executed in situ, along with bored piles, they are classified as displacement piles due to the fact that, throughout its execution, it exists the soil consolidation around the pile, as a result of an horizontal displacement imposed 2 by the drilling equipment. This compaction intends to improve the soil characteristics thus increasing the available area at the time of the loading application.

This technique uses a specific drilling equipment which is inserted in the soil by virtue of the application of a torsional movement, applied in the auger rod, and a downward thrust. The main difference between this technique and the remaining techniques is the drilling tool configuration that causes an horizontal displacement during the drilling process due to a zone with a greater diameter.

Drilling with the displacement system – full displacement piles.

[info]This is a common and cost effective technique in less stable ground conditions. There are several advantages to using the CFA piling method. These include:[/info]

- Very low levels of sound and vibration.

- Compared to conventional bored piles they can be installed very quickly and economically.

- They have high load-bearing, shear and movement capacities.

- They are suitable for a wide range of challenging ground conditions

- Piling rigs can be adapted to operate in conditions with low headroom and confined space

[info]This type of pile is the most straight forward of the auguring techniques. However drilling rates and geologically specific tooling determine the quality and cost effectiveness of this.[/info]

Ausipile can drill up to 2.8 meter in diameter and up to 68 meters deep if required in ideal conditions if required please feel free to contact our team at Ausipile to see what will best fill your needs.

[info]This is one of a most technically advanced techniques and is one of Ausipiles premium products and has been for some time.[/info]

Advantages

- Boring without bentonite support

- Allowing the jobsite installation plant to be minimized

- No vibration or impulse during construction

- Increase in productivity

- Rock drilling up to resistance of 8o MPa (unconfined compressive strength-UCS)

© 2026 Ausipile